Listen First, Then Guide

We understand your categories, buying patterns, and challenges before suggesting changes.

In manufacturing and trading, every small price change matters. Raw materials, logistics, spare parts, packaging, inventory — costs add up quietly. At Procure4Less, we help MSMEs and large enterprises spend smarter, remove hidden leakages, and strengthen procurement decisions without disrupting operations.

Some businesses rush toward large systems or complex tools. But real savings often come from simple, practical actions — better negotiations, disciplined sourcing, supplier comparison, and structured planning. Our approach is friendly, collaborative, and focused on cost saving strategies in procurement that work in day-to-day operations.

Smarter, Faster Procurement Starts Here

Manufacturing needs stable supply and predictable costs. Trading businesses deal with price pressure and inventory risk. Our methods support procurement cost optimization while keeping reliability and continuity intact.

We review pricing trends, terms, category spends, and vendor performance — helping your business reduce cost in business without compromising quality.

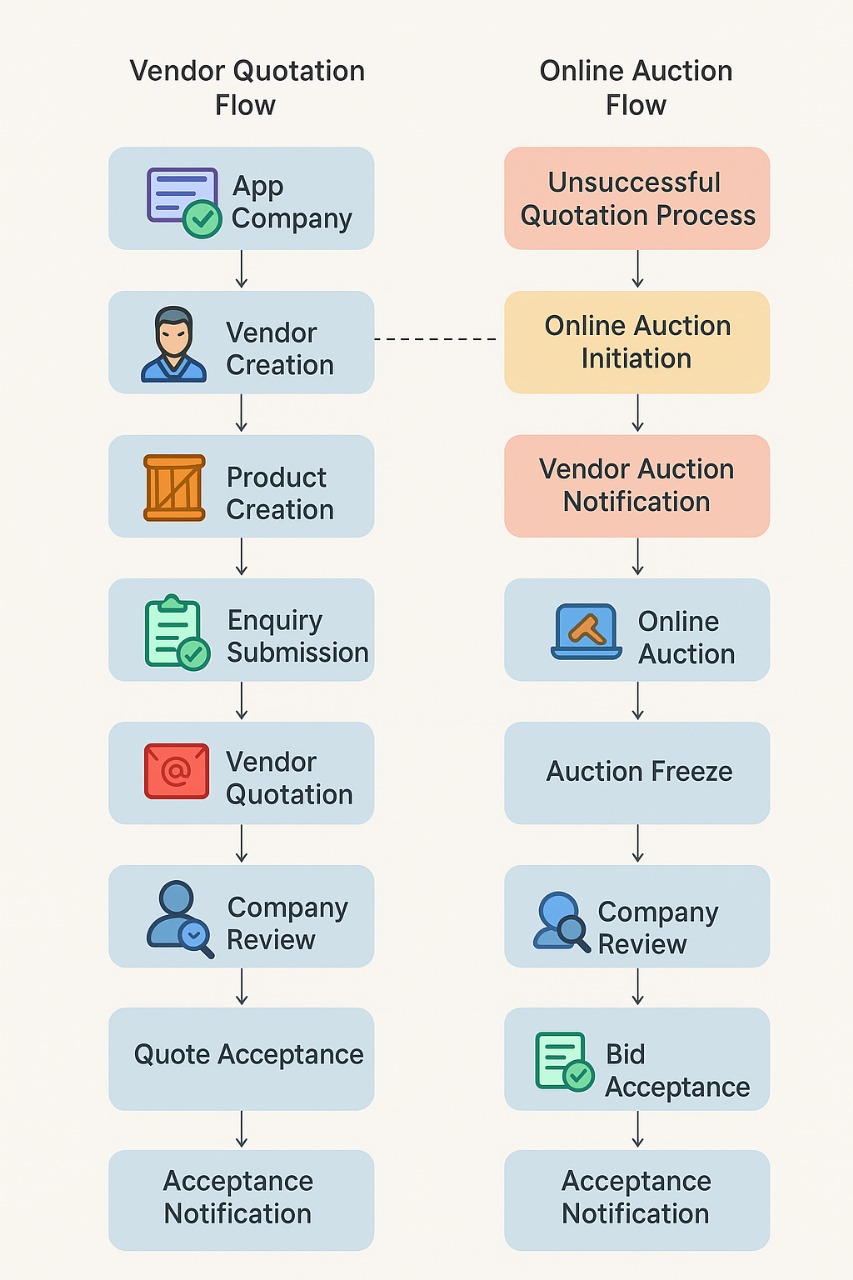

For suitable categories, we support structured buying through eauction, creating fairness, clarity, and competitive pricing for repeat or high-value requirements.

Whether your organisation is small, growing, or large-scale, our guidance adapts to your structure and maturity — always focused on reducing procurement cost with practical actions.

Always get the most competitive pricing with real-time vendor comparisons. Our intelligent benchmarking engine evaluates supplier performance, pricing history, and market trends—so you never overpay and always know you’re getting the best deal.

Our vision is to become the most trusted and intelligent procurement partner for businesses globally by providing automated, transparent, and cost-effective purchasing solutions.

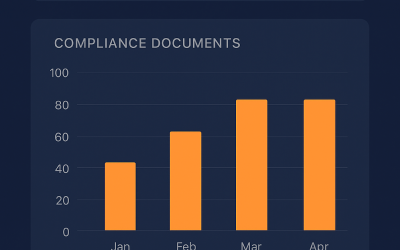

Procure4Less was established with the goal of simplifying the complex procurement lifecycle for modern businesses. We focus on leveraging AI and analytics to drive significant cost savings and enhance audit compliance for our clients.

Every organisation buys differently. Some purchase in bulk. Some handle multiple suppliers across categories. Some work with tight margins. Our services are designed to lower overall procurement spend, improve buying discipline, and build long-term value.

Clear insights, actionable savings opportunities, and practical steps your team can start applying immediately.

We study purchase data, categories, volume trends, payment terms, and vendor patterns. From there, we identify gaps, inefficiencies, and areas where your business can reduce cost in business without increasing risk.

No heavy jargon. No unnecessary complexity. Only improvements that work in real processes.

We help you design and apply cost reduction strategies in procurement such as supplier consolidation, renegotiation, price benchmarking, demand control, and structured sourcing.

Your team gains clarity. Vendors see fair competition. Pricing becomes consistent and measurable.

For suitable categories, we support eauction-based sourcing to improve pricing discipline and transparency, while keeping supplier relationships professional and respectful.

Savings are not a one-time exercise. We help build habits, governance, and controls that support ongoing procurement cost optimization and sustainable improvement.

Procurement should strengthen margins — not increase complexity. At Procure4Less, we work like a partner who understands challenges on the ground. We focus on real savings, steady improvement, and better decision-making that supports business growth.

Manufacturing depends on stable supply chains. Trading businesses operate on tight price margins. Our role is to help you remove avoidable costs, improve sourcing discipline, and bring structure to procurement decisions in a simple, human-friendly way.

We understand your categories, buying patterns, and challenges before suggesting changes.

We focus on realistic improvements your team can use every day.

Our support adapts to your size, structure, and growth stage — without forcing complexity.

Because our work is practical, people-centric, and results-driven — helping organisations apply cost saving strategies in procurement in a way that feels natural, measurable, and sustainable.

Power of creation. Pocket-friendly price.

It’s not about features for the sake of features. It’s about helping you achieve real business outcomes.

View Flowchart

We analyse your current buying patterns, supplier terms, price variations, and category spending. Then we suggest practical actions like better negotiations, supplier consolidation, structured sourcing, and cost reduction strategies in procurement that deliver real savings without disrupting operations.

Yes. Our methods scale smoothly. MSMEs benefit from simple, easy-to-implement improvements, while large enterprises gain structured optimisation, category control, and long-term procurement cost optimization support.

No — eauction is used only where it truly adds value, such as repeat or high-volume purchases. For strategic or specialised categories, we support balanced negotiations instead of competitive bidding.

Our approach maintains respect and transparency. The goal is not pressure — it is fair pricing, clarity, and disciplined sourcing that benefits both the business and the supplier ecosystem.

Not only price — we also improve total cost, including payment terms, inventory impact, freight exposure, and process-related inefficiencies that silently increase spend.

Every organisation talks about savings. But real impact is seen only when numbers change, processes improve, and teams feel confident about buying decisions. These case studies show how Procure4Less worked with manufacturing and trading businesses to make procurement simple, practical, and cost-focused — while keeping operations stable and relationships strong.

Each story reflects real business situations, real challenges, and real outcomes. The goal was never just to reduce prices — but to improve discipline, strengthen negotiation, control manufacturing cost, and build a culture of easy procurement where decisions became clearer and smarter over time.

This organisation was a mid-scale manufacturing company buying raw materials, consumables, maintenance parts, and packaging supplies. Over time, costs kept increasing, but nobody could clearly explain why. Prices changed frequently, supplier terms were inconsistent, and decisions happened in silos. The leadership team wanted clarity, control, and a structured approach to procurement cost reduction — without disturbing production flow.

The first step was listening. We spent time with the sourcing team, finance team, and plant supervisors. Everyone had their own version of the problem. Some spoke about urgent buying. Some mentioned supplier dominance. Others felt negotiations were done in a hurry. What became clear was this — procurement was working hard, but not always working smart.

We reviewed purchase history across one year. Item-wise pricing patterns, supplier concentration, urgent orders, and category-level variation. Small leaks appeared everywhere. No major mistakes — only many small decisions that quietly increased overall manufacturing cost.

Instead of big change on day one, we moved with small and practical steps. The goal was to make easy procurement — where the team felt supported, not pressured.

One major observation was that repeat items were purchased without benchmarking. A supplier would give a revised price, and the team would approve because production could not wait. We helped the team create simple comparison references and moved frequent items into structured negotiations. Over time, decisions became more confident — and the organisation was able to reduce procurement cost without conflict or disruption.

The next area was supplier mix. Some categories depended on a single vendor. Not risky — but expensive. We helped the team identify alternate suppliers, introduce fair competition, and maintain healthy balance. The idea was never to break relationships. It was to bring transparency and mutual respect.

In specific categories, we introduced eAuction as a structured process. But only where it truly made sense. Items with stable specifications and predictable demand delivered strong savings when vendors competed fairly. For strategic or technical materials, we stayed with guided negotiations instead. The principle remained simple — right method for the right requirement.

Gradually, patterns changed. Purchase approvals became calmer. Teams planned better. Urgent orders reduced. Pricing stabilised. And savings did not come from pressure — they came from discipline.

Within a defined period, the organisation achieved meaningful procurement cost reduction while maintaining supply continuity. More importantly, the team gained a sense of control. Decisions felt clearer. Processes felt lighter. Procurement stopped feeling stressful — and started feeling structured and supportive.

The leadership team shared something important — they were not only saving money, they were also building confidence. Costs came down in multiple categories, and the business was now managing manufacturing cost with awareness rather than guesswork. The journey did not end with one-time savings. It evolved into ongoing optimisation, continuous improvement, and long-term value creation.

This case study shows how easy procurement is not about shortcuts. It is about simple thinking, steady habits, and a people-first approach that makes a business truly able to reduce procurement cost in a sustainable way.

This organisation operated a large trading network handling bulk material supply across multiple regions. The business worked on tight price margins and depended heavily on market movement. Over time, cost pressure increased, inventory exposure grew, and profitability became unpredictable. The leadership wanted stability, discipline, and a clear path to procurement cost reduction without slowing business speed.

Trading firms often move fast. Decisions are made in real time, sometimes with limited negotiation cycles. Our goal was not to slow them down — but to bring structure around high-value categories so that pricing became predictable, and savings became repeatable.

We began by mapping category-wise spending, supplier overlap, and order frequency. It became clear that many orders were fragmented. The same category was sourced across multiple vendors without volume consolidation. This increased administrative effort and weakened negotiation strength.

Working closely with the team, we grouped similar items and built category-based sourcing clusters. This gave stronger visibility and created space for strategic negotiations. The organisation soon realised that cost reduction was not only a price issue — it was also a manufacturing cost-linked downstream impact because customers expected competitive pricing.

To support fairness and transparency, we implemented structured competitive events for suitable categories, including selected eAuction processes. Suppliers appreciated the clarity. Pricing started aligning more realistically with market trends. Instead of subjective discussions, decisions became data-led and objective.

Another key improvement area was payment terms and logistics exposure. Earlier, price reduction was considered the only saving measure. But freight, delivery patterns, and credit terms quietly increased working capital pressure. By re-balancing these elements, the business was able to reduce procurement cost while also improving cash-flow strength.

The team experienced something new — easy procurement did not mean oversimplification. It meant removing noise, avoiding repeated conversations, and building a steady rhythm in negotiations. Buyers felt more prepared. Suppliers knew expectations clearly. The environment shifted from reactive buying to controlled sourcing.

Over time, the organisation achieved consistent, measurable procurement cost reduction across priority categories. Margin pressure reduced. Inventory risk became manageable. Decision-making turned calmer and more confident.

But the biggest change was mindset.

Procurement was no longer seen as a support department. It became a value-driven function that helped protect profitability and business continuity. The journey also created a strong foundation for future optimisation and deeper category control.

This case study proves that when structure, fairness, and collaboration come together, even a fast-moving trading business can reduce procurement cost, strengthen relationships, and improve long-term financial stability — without losing agility or market speed.

This organisation managed multiple plants with independent buying teams. Each location worked differently. Some negotiated aggressively. Others prioritised speed. Prices varied for the same item across plants. There was no unified approach. Leadership wanted one simple outcome — a structured, people-friendly system that would steadily reduce procurement cost across locations while keeping operations smooth.

We started by building a single, combined view of spending. Category maps, vendor overlap, item-level comparisons, and supply dependency charts. What emerged was not inefficiency — but fragmentation. Everyone was doing their best, but without alignment.

The goal was not central control. The goal was coordinated intelligence.

We worked with local teams, not above them, and built shared strategies for key categories. Negotiations became collaborative instead of isolated. Plants exchanged knowledge and price benchmarks. Slowly, a culture of easy procurement began forming, where information flowed freely instead of being locked within departments.

For repeat materials with stable specifications, we introduced structured sourcing cycles. In select areas, eAuction events created competitive transparency and encouraged fair pricing. For technical or critical parts, we protected supplier partnerships and focused instead on value engineering and lifecycle manufacturing cost improvement.

Savings emerged naturally — not forcefully.

Beyond pricing, we addressed silent cost factors like urgent purchases, last-minute freight, inconsistent order splits, and unmanaged demand planning. By reducing chaos, the organisation was able to reduce procurement cost without any operational risk.

An important shift took place — decision-making slowed just enough to become thoughtful, but not enough to delay supply. Teams felt supported rather than audited. Procurement became clearer, calmer, and more meaningful.

Within the transformation period, the organisation achieved strong, sustainable procurement cost reduction, improved visibility, and smarter category control across all plants. But the real win was cultural alignment — one collective direction, one shared mindset, and one simple belief:

Cost reduction is not a one-time project. It is an ongoing journey of discipline, awareness, and continuous improvement.

This journey strengthened resilience, improved profitability, and built a foundation where procurement became a strategic value creator — not just a transactional function.

+91 9960662615

service@pearlcons.com

#50B, Kamarajar salai, Ashok nagar - Chennai

India

24 Hours / 7 Days Open

Office time: 09:00 AM - 6:30 PM

Let's discuss how ProcureLess can simplify your procurement and drive down costs instantly. Tell us a little about your business, and we'll show you how to get started.